Anxiety, frustration and elation

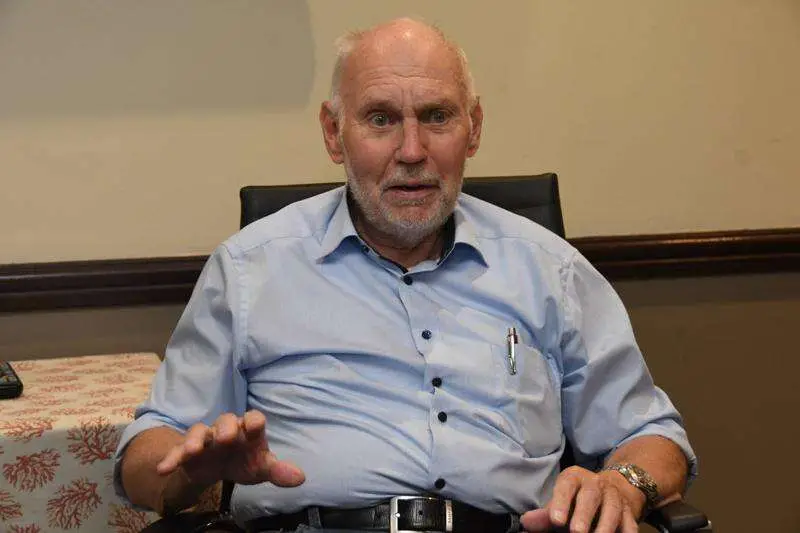

For 45 days Charles Johnston and Captain Peter Harren watched anxiously as the floating dry dock they and their partners purchased travelled from Bremerhaven, Germany, to Kingston, Jamaica.

“It was being towed across the Atlantic at almost the wrong time — hurricane season,” Johnston acknowledged on August 30, 2023 — six days after the vessel’s arrival.

Now, after seeing the 235 metre-long Panamax-size dry dock safely moored at the German Ship Repair Jamaica Limited (GSRJ) shipyard on the Sir Florizel Glasspole Highway stretch of Kingston Harbour, Johnston and Harren — giants in the shipping industry — are more relaxed.

“I cannot believe it,” Harren responded when asked to describe how he felt about the development. The comment triggers robust laughter from both men, most likely founded in sweet relief that the project on which they embarked more two decades ago finally came to fruition.

As Harren, the German shipping magnate who founded Harren & Partner Group in 1989, tells it, he has been running a feeder service in this region since the 1990s. Over time he found it difficult to access dry dock services in the region as the repairs, he said, took too long, “the bill was absolutely too high, and workmanship was lousy”.

“I had to go to Florida to a shipyard,” he related.

That set him on a mission to get an efficient dry dock established in Jamaica,

Eventually, Harren said, someone pointed him to a small boatyard at Harbour Head in Kingston owned by Jamaica Fruit and Shipping Company Limited — Johnston’s family business.

“We had it on a long-term lease from the Development Bank of Jamaica operating a boatyard. One of the conditions of the lease was, we should turn it into a shipyard,” Johnston explained.

He said that while he “never really paid too much attention to that clause in the lease”, he had thought of operating a shipyard before, “but just never found a way to do it”.

Harren’s approach resulted in Johnston, and now late Port Authority of Jamaica Chairman Noel Hylton, travelling to Germany in 2000 to discuss the idea of a floating dock with Harren.

“So we started to look at floating docks in Germany… there were a number of problems why we didn’t do it before, but one of the main problems was… none of us had run a shipyard, and running a shipyard is a horse of a different colour than running a boatyard,” Johnston told the Jamaica Observer.

Harren, he said, found some people in Germany with the expertise, but they walked away from the project when the global financial crisis hit in 2008.

“We then approached some guys in Holland [but] they told me they were doing something in Cuba. So, everywhere we went we couldn’t find somebody that would give us the expertise to run a shipyard and so we kept on looking. Then Peter went to Turkey and found a partner,” Johnston said.

That partner was the HAT-SAN Shipyard, one of the leading ship repair and ship builders in Turkey. The idea, Johnston said, was that the Turks would build the dock. However, the onset of the COVID-19 pandemic pushed prices through the roof.

Fortuitously at that time, Harren found a dry dock being sold by a friend in Bremerhaven, the port city on Germany’s North Sea coast.

Convinced that it was the best one they had seen, the Jamaican and German partners spoke with the Turks who told them, ‘If you don’t buy the dock, we will buy it.’

That was more than enough encouragement for both men who, by then, had interested Kim Clarke, managing director of Maritime and Transport Group of Companies, to join the partnership.

“Kim joined us about 12 years ago with a wealth of experience in the maritime industry and put a lot of energy into it,” Johnston told the Sunday Observer, adding that one of the founding partners is Kloska Group, a Germany company which offers a wide range of procurement, logistic, and service solutions for the maritime industry; expertise in engine repair; and the procurement of machinery, spare parts, etc.

Having secured the floating dock, the partners probably thought they had cleared all the major hurdles towards getting it here. However, red tape got in the way, creating a series of delays that resulted in some amount of frustration.

Asked whether, at any time during that process, he was worried that Harren and the other partners would have thrown in the towel, Johnston chuckled and said, “One time they gave me a deadline, yes. But one of the good things, I think, that encouraged them was that we were able to get funding in Jamaica from Jamaican companies.”

Chief among those companies was Sagicor Bank, which provided loan financing, and Mayberry Investments, which arranged for a number of local investors and pension funds to back the initiative.

“So we have Turkish shipyard expertise; German influence, shipping and technical expertise; Jamaican shipping expertise; and then we have Jamaican financial capital that have come to the party, plus Jamaican banking. So it’s quite a successful story, in that regard, that we have been able to put all the strings together,” Johnston said, even as he acknowledged that — but for the delays — the dock would have been here “maybe three years ago”.

That arduous experience, though, is now water under the bridge for Johnston and his colleague investors. Their immediate focus is to get the vessel, which was being operated in Germany as Dock V and has now been renamed Jam-Dock I, commissioned into service.

That can’t be soon enough, as they already have one of Harren’s ships booked for November.

How long will it take to effect the repairs?

“My hope is fast,” Harren said, triggering more laughter.

“It should take normally 10 to 15 days, so we hope we can finish it in that time… we have about five ships lined up already but we have to finish the first one,” Johnston explained after which he addressed the Sunday Observer‘s query about the cost.

“Ships have to dock, by insurance law, every five years. So when they come in and get inspected the repair work depends on how well they are maintained, how good the engines are, do the propellers need to be changed, all that stuff. So you can’t say what the price is; it depends on the ship.”

Expectations among the partners in this US$37-million investment is that it will provide about 500 jobs. Some of the specialised skills required, for example a dock master, do not exist here. However, Johnston and Harren said that the individuals with those skills will be retained on condition that they train Jamaicans. That, they said, will provide opportunities for students at Caribbean Maritime University which, over the years, has secured employment for a lot of cadets at Harren’s company.

With the interview about to end it was obvious that Johnston was still elated at the arrival of the floating dock and the seamless manner in which it was moored. In fact, he said that just before sitting down with the Sunday Observer he had a meeting with the marine pilots and congratulated them on the “fantastic job” they did.

“When it came in, first of all it was a beautiful morning, a beautiful day. Everything was lovely and she just came in like you couldn’t believe it,” Johnston shared with a warm smile. “She was docking at Kingston Wharves; she literally kissed the wharf, just literally kissed it. There was no bumping, just a little touch… everything went like poetry.”