Manufacturers urged to prepare early for exports

JAMAICAN manufacturers are being urged to shift from a reactive to a proactive mindset when it comes to export readiness, as companies that wait for demand before scaling operations risk missing key opportunities and damaging relationships with international buyers.

“If you’re to scale after you have sold a product, you’re late,” Private Sector Organisation of Jamaica (PSOJ) President Metry Seaga pointed out during a fireside chat at the Jamaica Manufacturers and Exporters Association (JMEA) Buyers Reception Cocktail last Wednesday at Jamaica Pegasus hotel in New Kingston.

Seaga, who is also CEO of Jamaica Fiberglass Products, emphasised that companies must avoid making promises they cannot keep, particularly when dealing with international buyers. He pointed to examples of local businesses that secured interest from overseas buyers but were ultimately unable to fulfil the orders due to lack of preparation.

“Don’t wait until the demand hits you to look and gear up; be prepared to gear up way before that,” he stressed.

Overpromising, the audience was told, can have a ripple effect, especially when a buyer’s first experience with a Jamaican manufacturer is a negative one. As such, a single failed transaction can damage the reputation of other businesses in the industry and impact Jamaica’s broader credibility in global markets.

“You’re not just representing your company, you’re representing Jamaica. What they’re going to walk away from is, ‘I had this experience with a Jamaican manufacturer’,” warned Marc Frankson of Designs by Marc Limited.

Experts agree that building a solid foundation for export success includes more than having a good product, it requires the right systems, financing, and relationships in place. Resources are available through agencies such as the Trade Board and the JMEA to help businesses navigate the export process.

But beyond technical support, manufacturers are being urged to focus on relationship building as a core business strategy. Maintaining strong connections with suppliers, logistics partners, and customers is key to long-term success and resilience. Breaking trust with a buyer can be difficult to repair, especially in industries that rely heavily on repeat orders and strong reputations.

“My suggestion to any of the manufacturers here is to build relationships, not only with your customers and the people you’re about to sell to, but also with the people who form the chain of command for your product,” said Seaga. “You can’t build a product without raw material, so make those relationships strong.”

Following the adverse effects that the COVID-19 pandemic had on businesses, manufacturers are also being urged to reassess their operations and build more resilient supply chains. Industry players say the disruptions of the past few years have underscored the harsh reality that many companies were unprepared for sudden global shocks.

“For a long time we were just comfortable,” Frankson admitted. “We knew what each day looked like, what the next week would bring. Then COVID turned everything on its head.”

That experience exposed the critical vulnerability of over-reliance on single suppliers. In response, Designs by Marc committed to becoming more agile and better prepared for future disruptions by having more suppliers within its database.

“Instead of having this one supplier that we depended on, because the price was good and they were dependable, we needed to build up our database and have three, four suppliers for that same thing, for that particular raw material in different parts of the world,” he explained.

Today, with supply partners located in the Far East, the United States, and South America, the company has built the flexibility needed to respond more effectively to global shifts. The transition to a more agile model has also contributed to improved customer satisfaction. While delays and supply issues may be understandable from a business perspective, customers ultimately expect on-time delivery.

While Frankson encourages manufacturers to take a similar approach, some segments of the industry, such as food production, face greater challenges in diversifying suppliers. Relying on multiple sources can affect taste profiles, disrupt quality systems, and compromise product consistency. For these manufacturers, the recommendation is to shift away from monthly ordering and instead plan much further ahead, securing longer-term forecasts from buyers to support better supply chain planning.

With tariff measures hitting all regions, manufacturers are being encouraged to reposition themselves and view the challenges as opportunities for growth. Frankson noted that tariffs could open new doors for local producers previously edged out by cheaper competitors.

“A year ago I couldn’t compete with X company, which supplies this company in the US, but now that they are going to be tariffed 25 per cent, maybe I can be more competitive,” said Frankson.

Seaga concurred. “It’s a little-known fact how good we are at what we do. We make exceptional products. We make world-class products. Maybe our prices are not as China’s as yet, but with the tariffs that are coming now. Who knows, we might just be there,” he said.

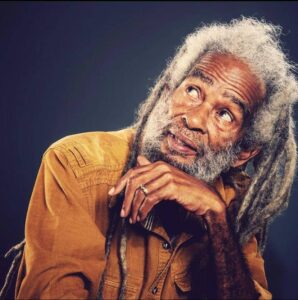

Private Sector Organisation of Jamaica President Metry Seaga encouraging manufacturers to be prepared for product demand during the Jamaica Manufacturers and Exporters Association Buyers Reception Cocktail last Wednesday at Jamaica Pegasus hotel in New Kingston.